Smeesegment vir Shantui Komatsu CAT

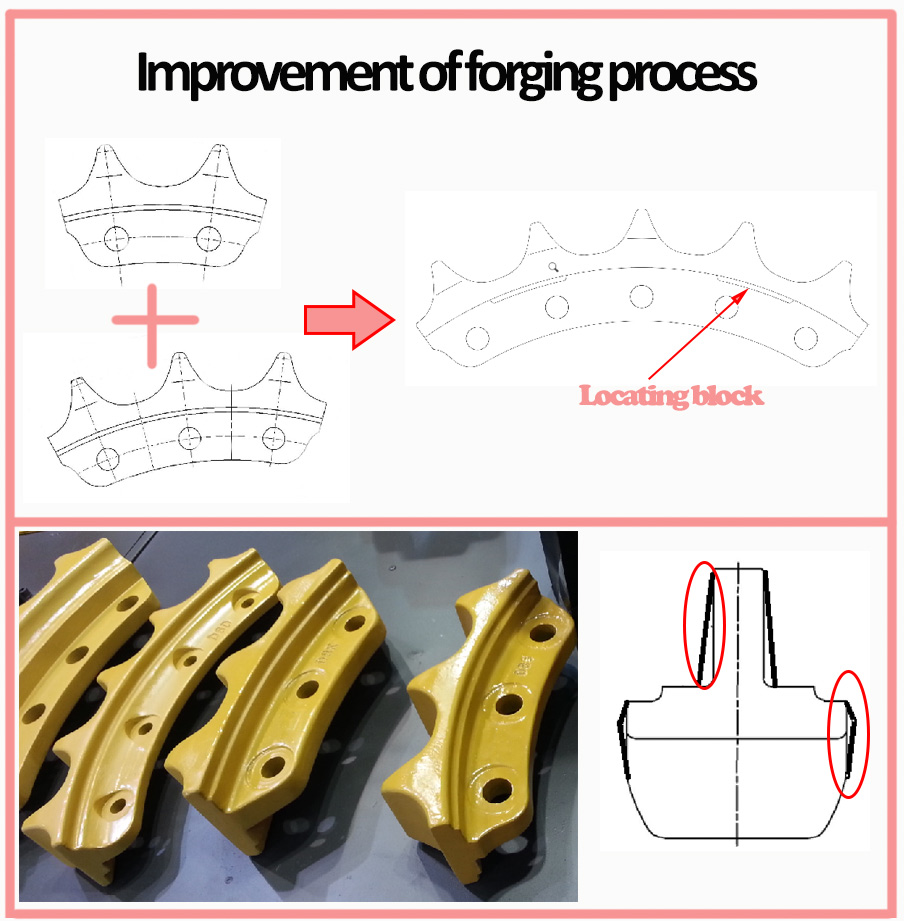

Verbetering van die smeeproses

Deur van twee of drie tande na vyf tande te verander, word die voorkoms van tandblok-losmaak verminder. Die verandering van die posisioneringsirkel na 'n posisioneringsblok verminder masjineringsfoute en interferensie tussen die posisioneringsirkel en die installasie-oppervlak wat deur hittebehandelingsvervorming veroorsaak word.

As gevolg van die smeeproses, die sy- en flensoppervlaktes van diesegment In die regop smeeproses moet 'n sekere trekhoek behou word, en die bewerkte oppervlak van die gesmede halfafgewerkte produk moet verwerk word.

Model wat ons kan verskaf

| SEGMENT | ||||||||

| Model | OEM | Toonhoogte | Tand | Vakansiedae | Diafragma (mm) | Gewig | Handelsmerk | Ander OEM (BERCO) |

| DH08 | 111H-18-00001 | 154 | 3 | 3 | 17.5 | 4.1 | shantui | |

| 111H-18-00002 | 4 | 4 | 17.5 | 5.5 | shantui | |||

| SD13 | 10J-18-00043 | 190 | 5 | 5 | 19.3 | 10.75 | shantui | |

| DH36 | 1175-18-00009 | 228.6 | 6 | 6 | 26.5 | shantui | ||

| 1175-18-00035 | 5 | 5 | 26.5 | |||||

| SD16, D65, D60, D85ESS-2 | 16J-18-00014H | 203.2 | 3 | 3 | 23.5 | 8.5 | shantui/komatsu | 14X-27-15112/1,141-27-32410,144-27-51150,615-4149,KM2111,KM162 |

| (16J-18-00049) | ||||||||

| SD22, D85 | 154-27-12273A | 216 | 5 | 5 | 23.5 | 15 | shantui/komatsu | 155-27-00151,615-4150,KM224 |

| SD32, D155 | 175-27-22325A | 228.6 | 3 | 3 | 26.5 | 12 | shantui/komatsu | 175-27-22325/4 17A-27-11630,KM193,17A-27-41630 |

| SD52, D375 | 185-18-00001 | 280 | 5 | 5 | 28.5 | 33 | shantui/komatsu | 195-27-33110/1, KM1285 |

| SD90, D475 | 1189-18-00001/ | 317.5 | 5 | 5 | 31.5 | 43 | shantui/komatsu | |

| 198-27-42260 | ||||||||

| D50, D41, D58, D53 | 131-27-61710 | 175 | 3 | 3 | 19.5 | 6 | Komatsu | 131-27-61710, 131-27-42220, KM788 |

| D5B | 5S0836 | 175 | 3 | 3 | 18 | 5 | KAT | 6Y5244, CR4408.7P2636 |

| D6D/C/G | 6T4179/6T4179/6P9102 | 202.8 | 5 | 4 | 17.8/20.8 | 11.57 | KAT | 6Y5012,5S0050,7P2706,CR3330,CR3329,8P5837,8E4365/CR5476,117-1616 |

| D6H/R | 6Y2931/1026677 | 202.8 | 5 | 5 | 17.8 | 11.5 | KAT | 7G7212, 8E9041, 7T1697, CR5515, 173-0946 |

| D7G/E/F | 8E4675/8E4675/8E4675 | 216 | 5 | 4 | 20.8 | 14.7 | KAT | 5S0052, 3P1039, 8P8174, CR3148 |

| D8N/R.D7H/R | 7T9773/6Y2354, | 215.9 | 5 | 7 | 20.8 | 16.4 | KAT | 6Y3928,CR5050,9W0074 |

| 6Y2354/7T9773 | ||||||||

| D8N/R.D7H/R | 314-5462 | 215.9 | 5 | 5 | 20.8 | 16.4 | KAT | CR7160 |

| D8K.D8H | 6T6782/6T6782 | 228.6 | 3 | 3 | 24.5 | 12 | KAT | 2P9510,5S0054,CR3144 |

| D6N.D6M | 6I8077/6I8077 | 190 | 5 | 5 | 18.5 | 9 | KAT | 6I8077/8,CR5875 |

| D9N | 7T1247 | 240 | 5 | 6 | 24.6 | 23.98 | KAT | CR4686 |

| D10N | 6T9537 | 260.35 | 5 | 6 | 27.61 | 26.7 | KAT | CR5047 |

| 832 | 632-7793 | 228.6 | 3 | 5 | 26.5 | 11.63 | KAT | |

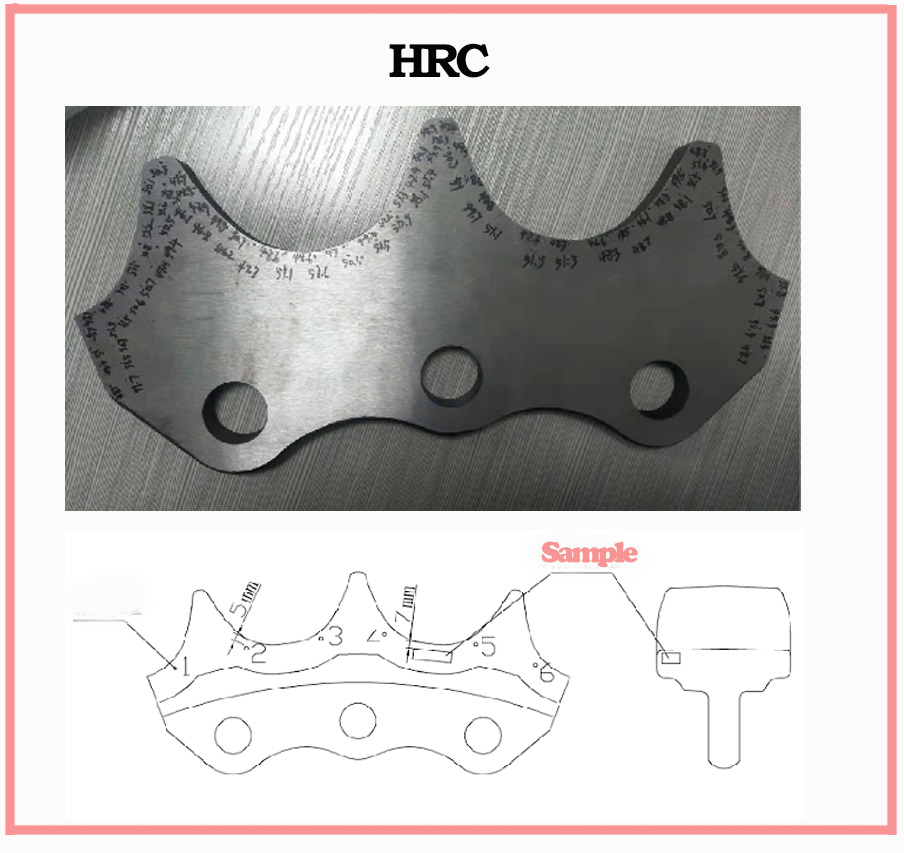

HRC

As gevolg van die smeeproses moet die sy- en flensoppervlaktes van die segment in die regop smeeproses 'n sekere trekhoek behou, en die bewerkte oppervlak van die gesmede halfafgewerkte produk moet verwerk word.

Verpakking